Barrel-by-barrel sampling of free SO2 can potentially help winemakers prevent unnecessary and expensive barrel downgrades.

—David Sommer, CTO, BarrelWise Technologies

Free sulfur dioxide (SO2) is unique amongst common wine chemical metrics, as it is at once a symptom and a treatment. Free SO2 protects wine by scavenging oxygen and interrupting microbiological activity is, itself, consumed in the process (ignoring a lot of complex chemistry). This makes accurate measurement and proper management of free SO2 levels during barrel aging particularly important.

If free SO2 is too low, the wine is at an elevated risk for developing microbial or oxidative faults. Over-addition can also cause issues, as high SO2 levels start to run up against sensory and, eventually, regulatory thresholds.

In a recent survey, conducted at BarrelWise, 97 percent of winemakers (n=70) agreed that maintaining correct free SO2 levels in barrels of ageing wine is important to maximizing wine quality. Despite nearly unanimous agreement on its importance, the most common methods in the industry for measuring and managing free SO2 in large groups of barrels rely on one underpinning assumption: all barrels are the same.

All barrels are not the same. There is significant variability between them—that is, afterall, why barrel groups are made up of a variety of oak types, cooperages, and ages, and why blending from barrels is arguably one of the most important roles of a winemaker. Barrel-by-barrel variance of sensory characteristics are sought, as they lead to a wide gamut of aromatic blending opportunities, ultimately leading to more complex, high-quality wines.

The apparent contradiction between free SO2 management strategy and observed barrel-by-barrel sensory variety made us interested in whether this barrel-by-barrel variation extends to free SO2 levels and, if so, what correlation this has with barrel performance and sensory outcomes. The concern being that barrel-by-barrel variation of free SO2 within a group may lead to some barrels being at elevated risk for microbial or oxidative faults and/or over-addition of sulfites in other barrels.

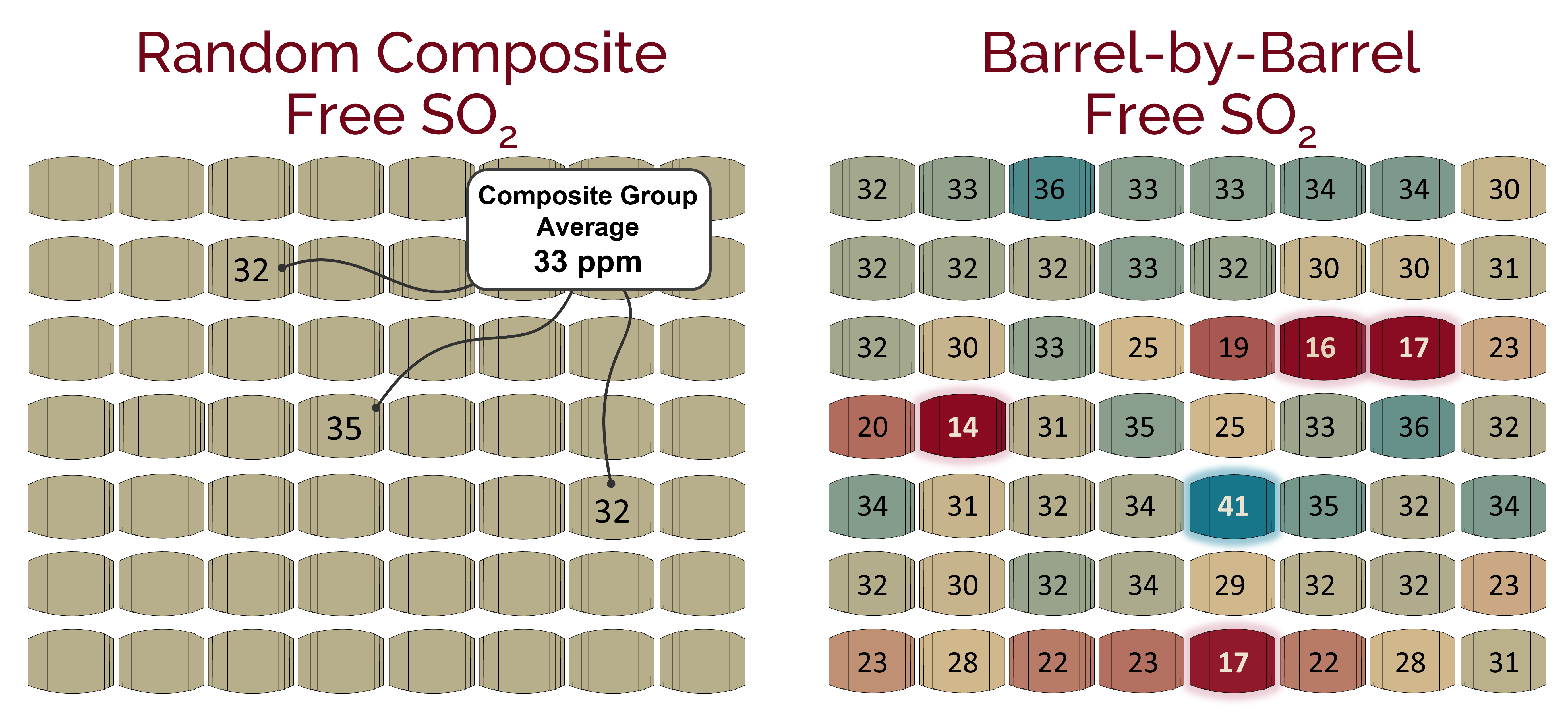

To investigate, we sampled each individual barrel in a group of 56 barrels of Merlot, consisting of a variety of coopers, with barrels ranging from first to third fills. A typical winery process of collecting a composite sample from a few “random” barrels (which often happens to consist of the easiest barrels for the cellar crew to reach) would most often indicate a free SO2 level of around 35 ppm, a reasonable set point of 0.45 ppm molecular SO2 for this wine.

Analysing every barrel in the group revealed that the barrels varied between 14 and 41 ppm free SO2. Four of the barrels were deemed critically low by the winemaker (less than 0.22 ppm molecular SO2) and required individual additions to correct them.

This limited data set suggests a rate of around 7 percent of barrels being sufficiently far from the composite group average. If we assume that only half of these premium barrels develop an undesired oxidative or microbial impact over their ageing period that results in a downgrade to a lower priced label, the financial impacts become quite striking. If four barrels from a one-hundred-barrel group become downgraded from a $60 flagship SKU to a $18 mid-tier SKU, the result is a $50,000 lost revenue opportunity.

What causes some barrels to bind SO2 faster than others? The reasons are complicated, but can include a barrel’s use and cleaning history, different microbiomes between barrels, human error (i.e.: missed additions, open bungs, contamination), and barrel construction. BarrelWise is conducting active research with our winery partners to better understand the cause-and-effect relationship between barrel factors, wine chemistry, sensory, and wine quality outcomes.

Barrel-by-barrel sampling of free SO2 can help to identify outliers, and potentially give winemakers the tools to prevent unnecessary and expensive barrel downgrades. Barrels are where many of the most expensive wines spend most of their in-winery lifetime, yet—until now—barrel management is generally conducted in the dark, with a very dim flashlight.

_______________________________________________________________________

David Sommer is the CTO of BarrelWise Technologies. He has his BS and MS in mechanical engineering from the University of Waterloo and is currently pursuing his PhD at the University of British Columbia where his research is focused on optical diagnostics and energy systems. He has worked as a sales engineer for Toshiba, a space systems engineer for the Canadian Space Agency, and a consultant for RDH Building Engineering. Sommer’s focus at BarrelWise is to direct product development and manufacturing, and to ensure the technology portfolio is aligned with the needs of the current and future customers.

_______________________________________________________________________

Sommer will be speaking at WINExpo 2021. His session, Variance in fSO2 Across Barrels and the Quality Impact of Precision-Dosing will dive into specific winery case studies surrounding variances in barrel specificities as it relates to their effects on free SO2 and the resulting wine quality. Learn more about WINExpo and register.